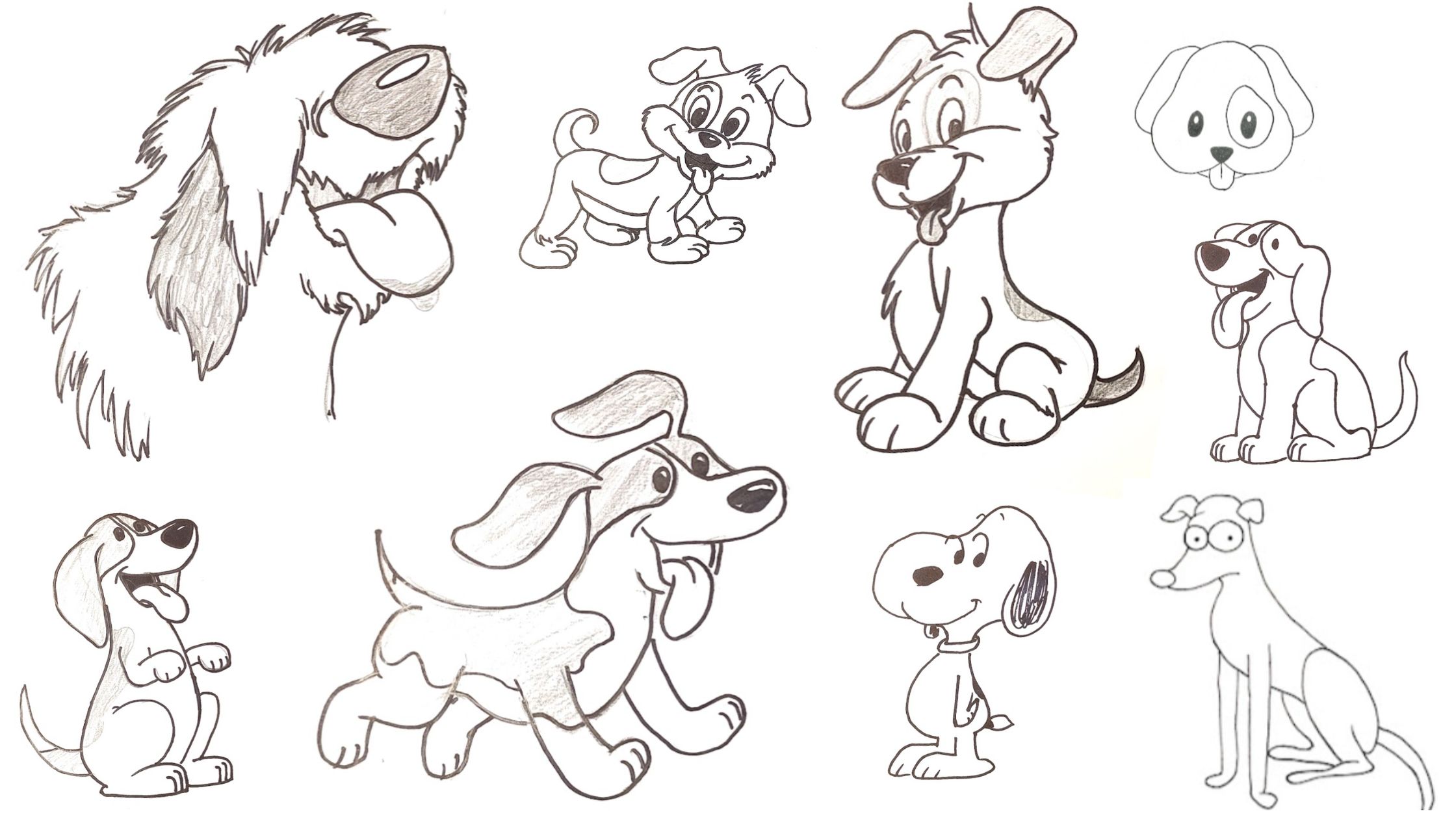

Cómo dibujar un perro fácil a lápiz para niños

Por fin vas a tener una guía paso a paso para aprender cómo dibujar un perro fácil a lápiz. Prepara papel y lápiz… que empezamos! En esta sección encontrarás un montón de videos de dibujos de distintas razas de perros (beagle, bobtail-pastor inglés, pastor alemán, galgos,…) y además tenemos dibujos de conocidos perritos del cine … Leer más